How to Identify Quality Men’s Dress Shirts-The Dress Shirt Guide

The dress shirt has a crucial role in men’s wardrobe. It is directly in contact with the skin and plays a suspension role between body and jacket movements.

To create a prime-quality dress shirt that needs a quality fabric, an experienced tailor, and specific craftsmanship indifferent, it is bespoke, made to measure, or ready to wear.

The shirt is a second element of the professional’s wardrobe after the suit and needs special attention when purchasing the shirt.

The following factors we should take into consideration during the dress shirt purchasing :

- Our face and body shape

- Our Neck length and diameter, proportion to the head and the body

- our job and social life

- Shirt collar shape and size

- The lapels and collar of the jacket

- Fabrics pattern, color & quality

I am covering most of the essential details in this article, which will help you choose the right shirt for your wardrobe.

1) Fabrics:

1) Fabrics:

1) Fabrics:

Fabrics, the crucial element of quality shirts. To identify high-quality material, we need to know the following factors:

Fiber quality and Yarn count (diameter):

The thickness and length of the fibers play an essential role in fabric quality.

Yarn measuring within thread count in micron or super(‘s). Higher thread count, softness, length of the fibers, sophisticated technology, and advanced machinery are essential in yarn quality.

The quality of the fiber is another aspect of this sophisticated process, which depends on the provenience, location, climate, length, and when the fiber is cultivated.

Weaving and finishing techniques:

Today, we have advanced technology for weaving and finishing the fabrics in a silky touch and smooth shell finishing. Fabrics processing techniques, together with the type of fiber, determine the fabrics’ quality and value.

Here are some of the verification techniques for prime-quality fabrics.

a) Weaving density:

High-density weaving is characteristic of premium quality fabrics. It is like tv pixel density (DPI), high-density of pixel means clear quality image, and high-density weaving means high-quality materials.

b) Touch and feel:

Quality shirt fabrics always have exceptionally silky, smooth, soft, and pleasant touch; It’s usually colder than room temperature and thin weaving construction.

Good-quality fabrics are thin, dense, and heavy feeling on hand, but the low-quality materials are thick and light in hand feeling and low-density weaving.

2) Shirt stitch density

Stitching density is an excellent indicator of verifying the prime-quality shirt. The number of stitches in one inch or centimetre is essential for appreciating the shirt’s quality. It is crucial because this way, we can determine if the shirtmaker used high-quality fabrics. High-density stitches can be used only in higher thread count and tightly woven fabrics, like 20 to 27 step stitches per inch, which is impossible in low-density weaving fabrics. Using the same number of stitches in low thread count fabrics will cut the material at the sewing line.20 to 27 stitches per inch is considered a good quality shirt with an elegant look and durability. Low-density shirt fabrics require slightly larger stitches to not destroy the material, generally up to 14 step stitches per inch. To understand the quality of the shirt, we need to count the number of stitches in one inch; good quality shirt must have between 20 to 27 stitches per inch.

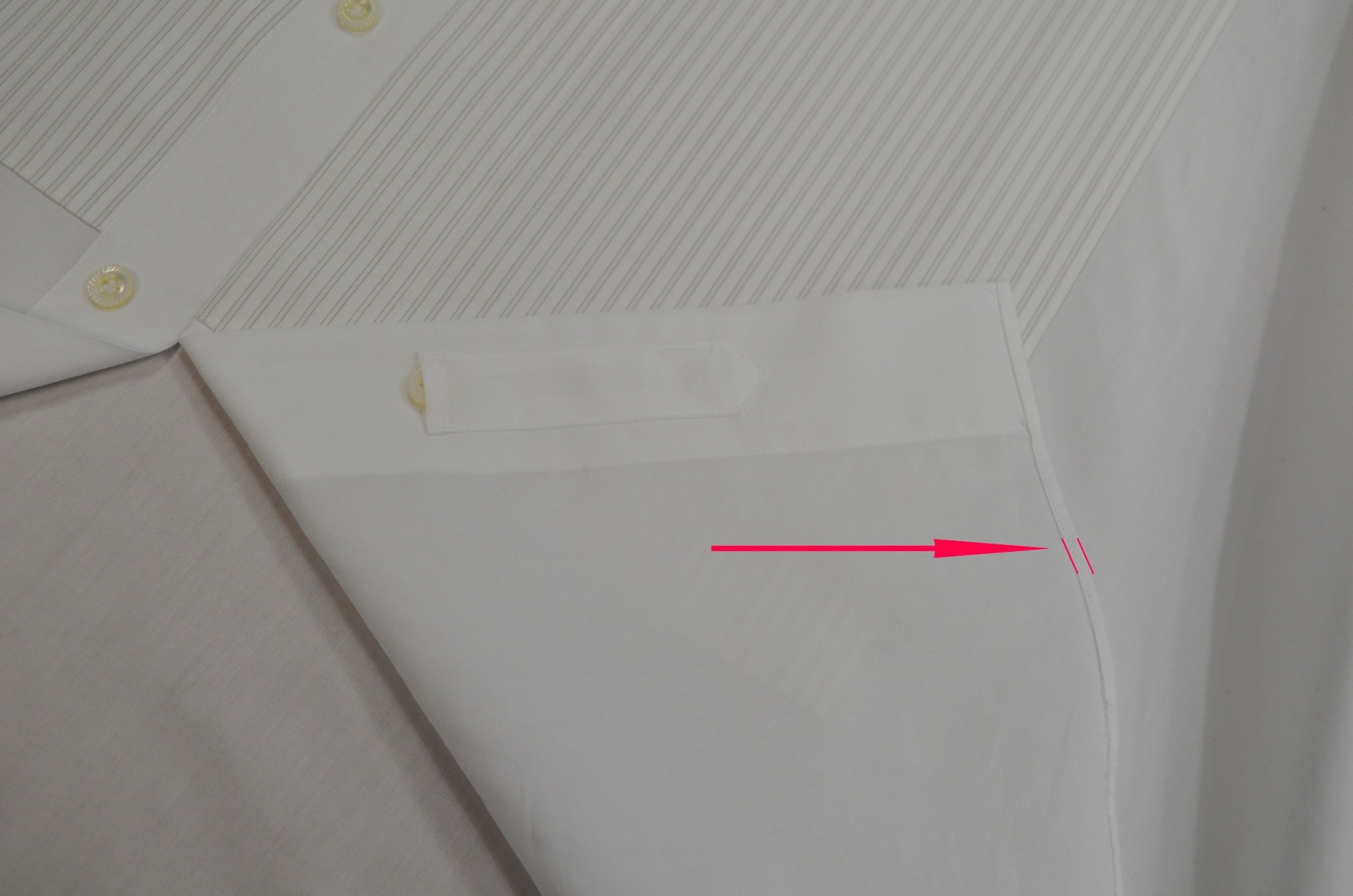

3) Stitch distance from the edge ( Hemming line)

3) Stitch distance from the edge ( Hemming line)

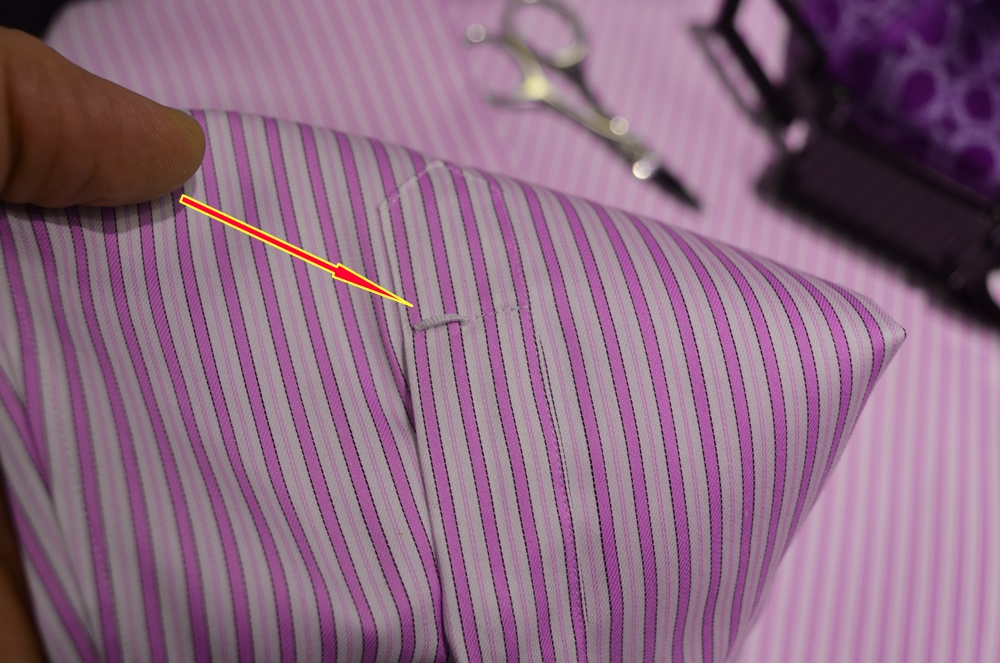

Another detail to verify the quality shirts is the hemming stitch line on the bottom. You can check the stitch distance from the margin. The smaller feature is better, under 3 mm considered very good, because to sew 1 to 3 mm, Higley experiences tailoring skills. Check the consistency of these stitches all over the shirt. Another detail on hemming stitching is that wrinkling and weave, especially on the bottom part of the shirt, need to pay particular attention to the curvy shape.

4) Handmade Pick stitching ( Decorative hand stitching )

Pick-stitching is still part of the quality shirt. Before, it was exclusively used in high-quality shirts, but many shirt makers have this detail on their shirts these days. It is another element of a high-end shirt that often features decorative hand pick stitching along the seams. It indeed looks, but it is an excellent indicator to understand manufacturer attention to the small detail.

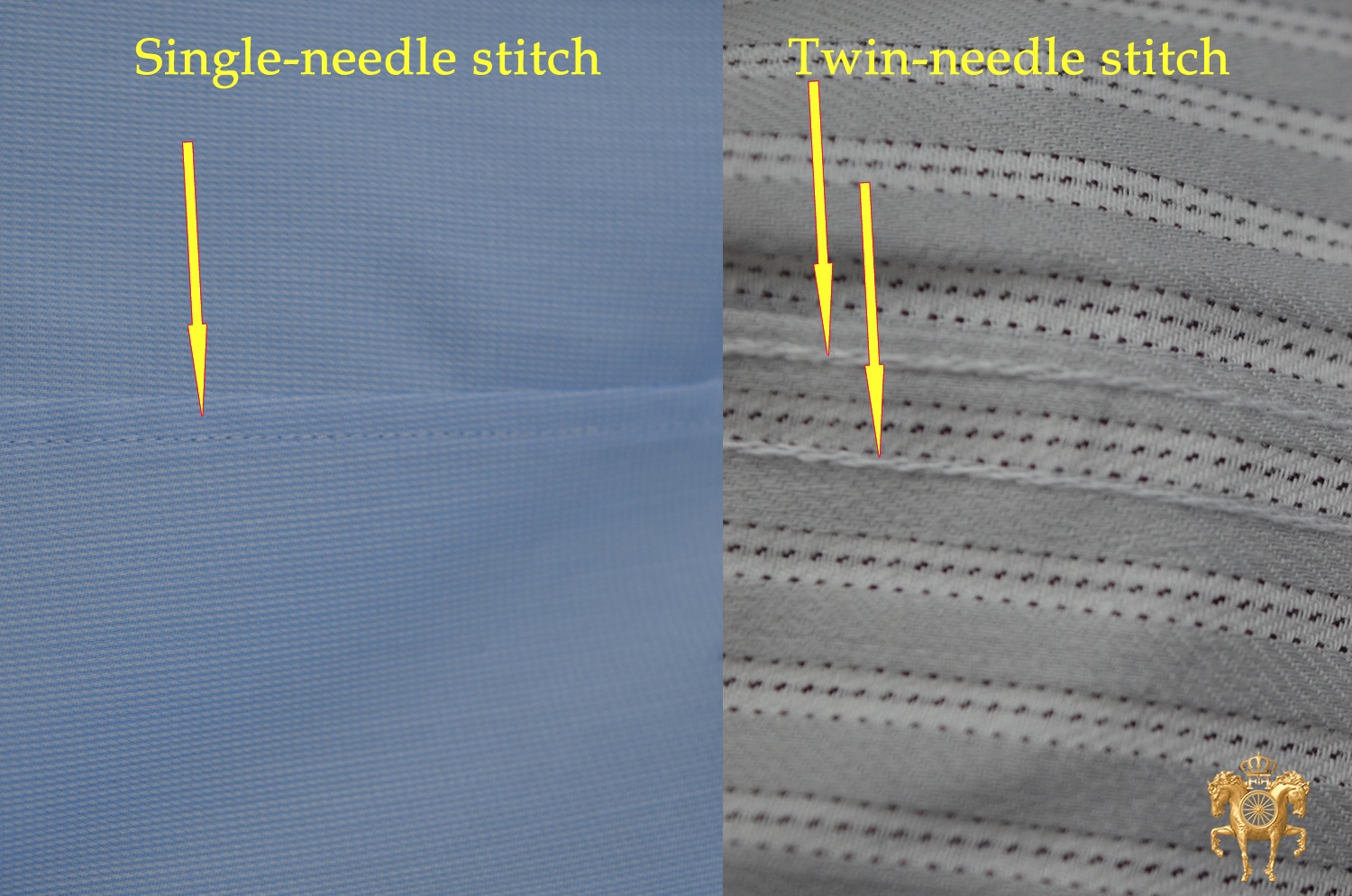

5. Side Seams

To obtain a cleaner look and dressier appearance on side seams, you need to use single-needle stitching in 3 mm or less. High-end shirtmakers always use a single-needle stitch. It is another future for the prime quality shirt. The low-end shirt future is with twin needles. This stitching future is mostly used on cheap and casual shirts.

The major problem in twin-needle stitching is wrinkling, look, and functionality. The seams with double-needle stitches will get wrinkling.

Another aspect of twin-needle stitches is time spending on sawing, three times less than single stitches. The most critical element in tween stitch is the shirt’s body sides seams stitching together with the shirt sleeve seams in a continuous line and creating an uncomfortable feeling in body movement. By the body movements, your shirt will come out from your pant.

6. Collar

6. Collar

The shirt collar is the most visible and essential part of the shirt, which we need to pay great attention to the following details.

a) The interlining used inside the shirt collar maybe use woven or none-woven paper base fused and non-fused depend on construction. The collar is made of three-layer materials. Upper, middle, and lower, the inner side is interlining, and the other two are shirt fabrics. The shirt collar inner assembly can be fused at the front side only and backside or on both sides. Un-fused is the best option, and we need a high skilled tailor to do it. That is not mean a fused collar is not an excellent option. High-Quality fused collars provide a crisp collar, the quality of interlining, construction, and craftsmanship is highly essential to make a good quality shirt.

b) The purpose and function of the interlining

The reason for using interlining in shirt collars and cuffs is to create support for multiple laundries, a crisp look, and a better shape. Using different thicknesses and softness interlining forming a distinct look and functionality for a specific event, like a dressy evening and a casual shirt.

c) Collar buttonhole shape and button size:

The buttonhole on the collar should make at 45 degrees. The button size is better to be slim and small for functionality reasons.

d) The stitching density of the collar should be between 20 to 27 stitches per inch.

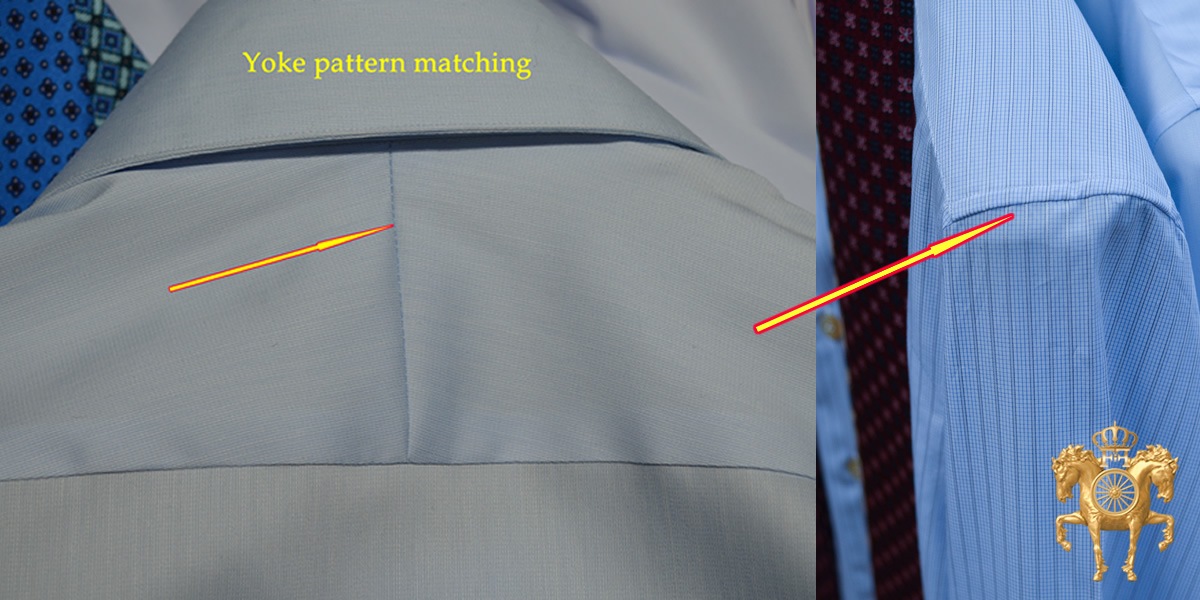

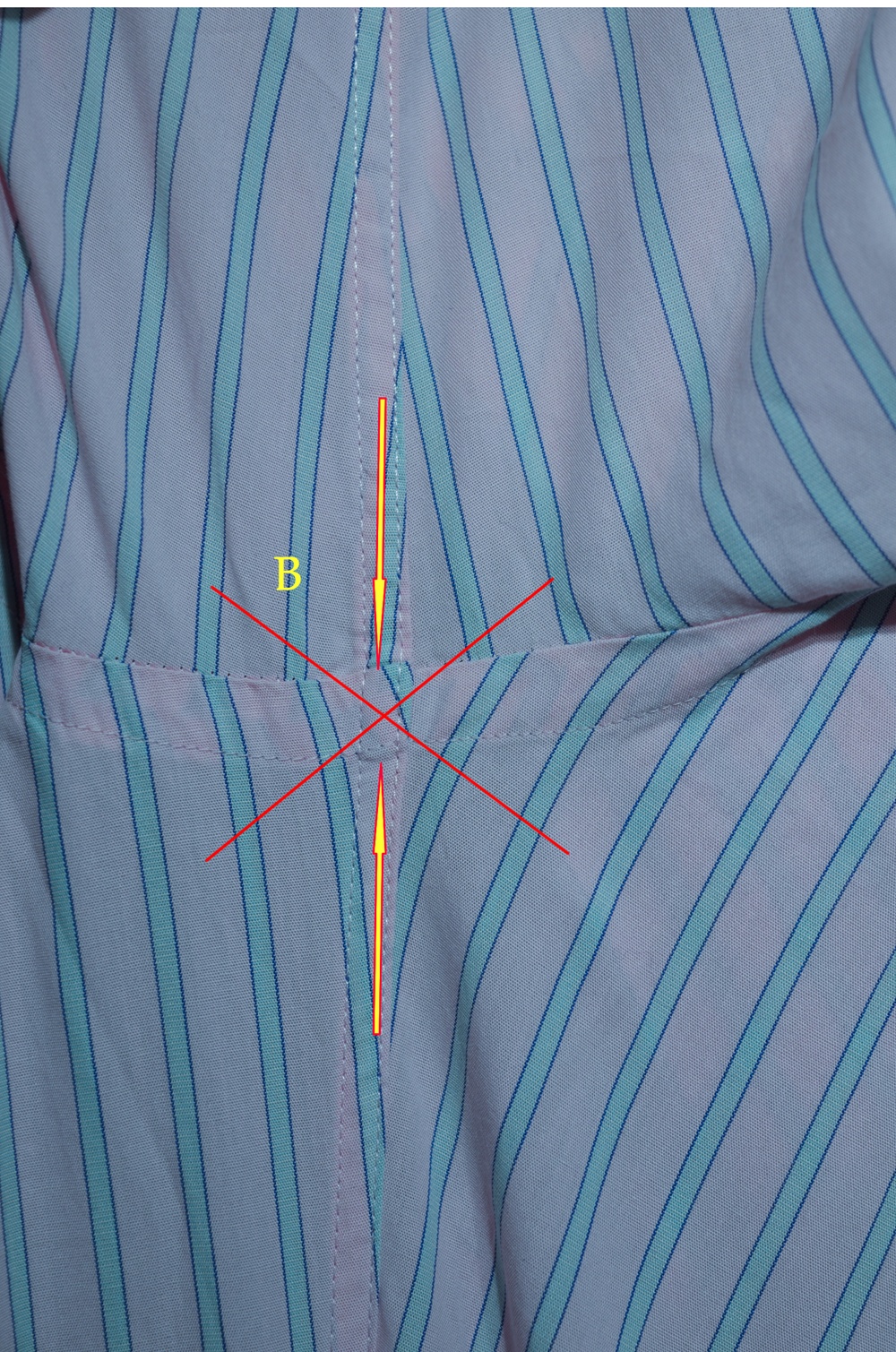

7) Matching pattern

7) Matching pattern

Matching pattern

A matching design is another detail in a high-quality shirt. You can check the shoulder on the joint part between the top sleeves and shoulder, the back yoke in the joint portion, and the sleeves vents. The yoke is the backside of the shirt, which connects the neck to the shoulder. The yoke has two layers and makes sure this part is split in a diagonal shape (45 degrees) and perfectly matches the pattern line.

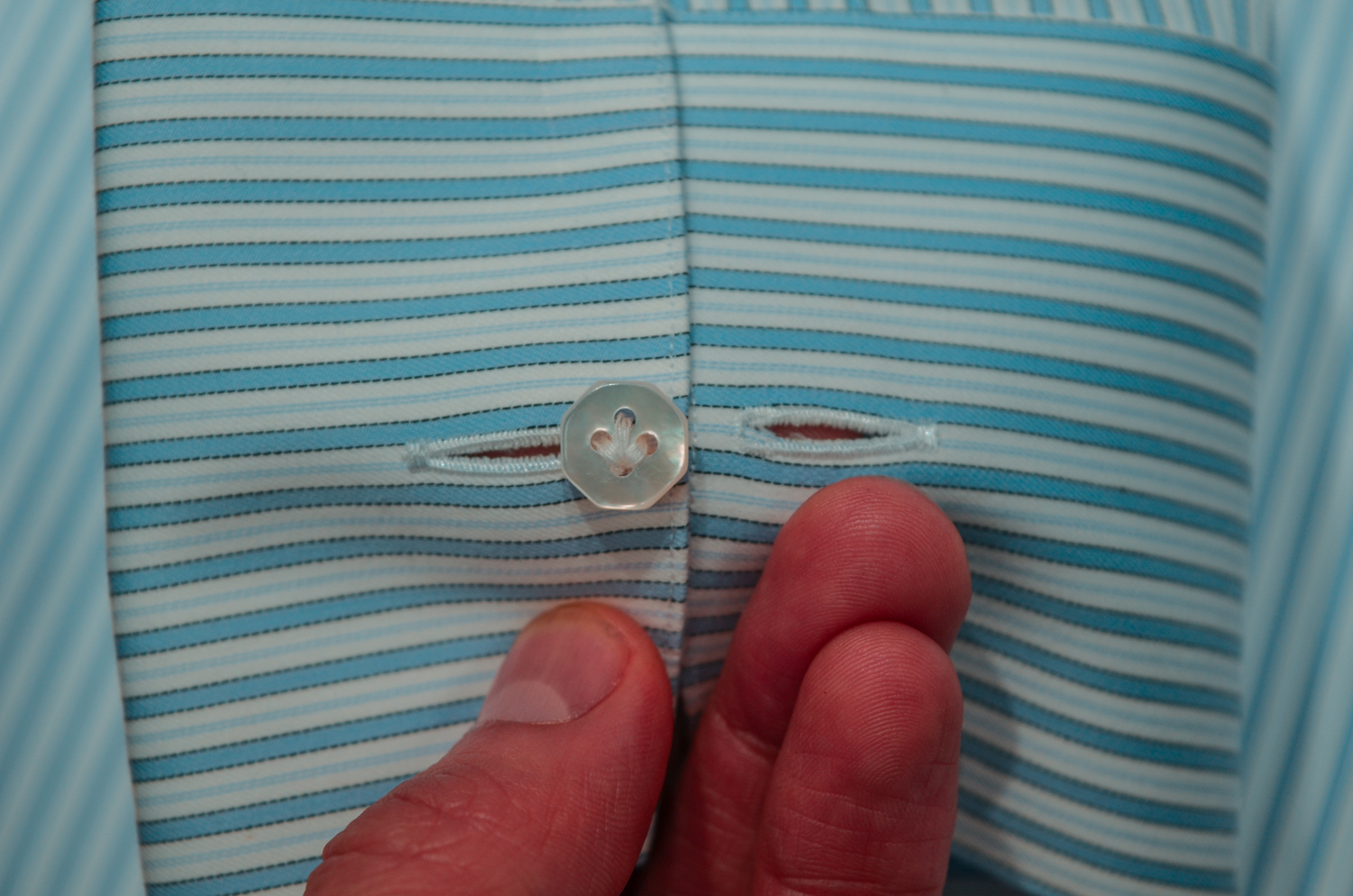

8) Buttons

Mother of pearl (MOP), shell, or Stone buttons are the best choices for the quality dress shirt, and You can identify the MOP buttons from polyester and plastic with the following methods:

a) The temperature, all shell buttons, always are colder than room temperature. You can use your tongue or face to feel the temperature differences.

b) By sound, hitting two buttons together will hear the stone or glass sounds)

c) Burning by lighter, heating the button will change the color to black or grey instate polyester buttons will burn entirely like a plastic.

d) Braking the Button. If you have an extra button, breaking will observe like smashing the glasses.

Other button options are horn, wooden, metal, plastics. The shell button is the best option and becomes the symbol of luxury in the fashion industry because of look, characteristics, and quality.

The pearl buttons’ are available in different thicknesses and shapes, and shell buttons are available from 1.5 mm to 6 mm. The thicker buttons are beautiful, but it is hard to cut in 6 mm and find the shell in that thicknesses in significant quantity for a specific color. Some quality shell buttons need to be cut individually with a hand drilling machine.

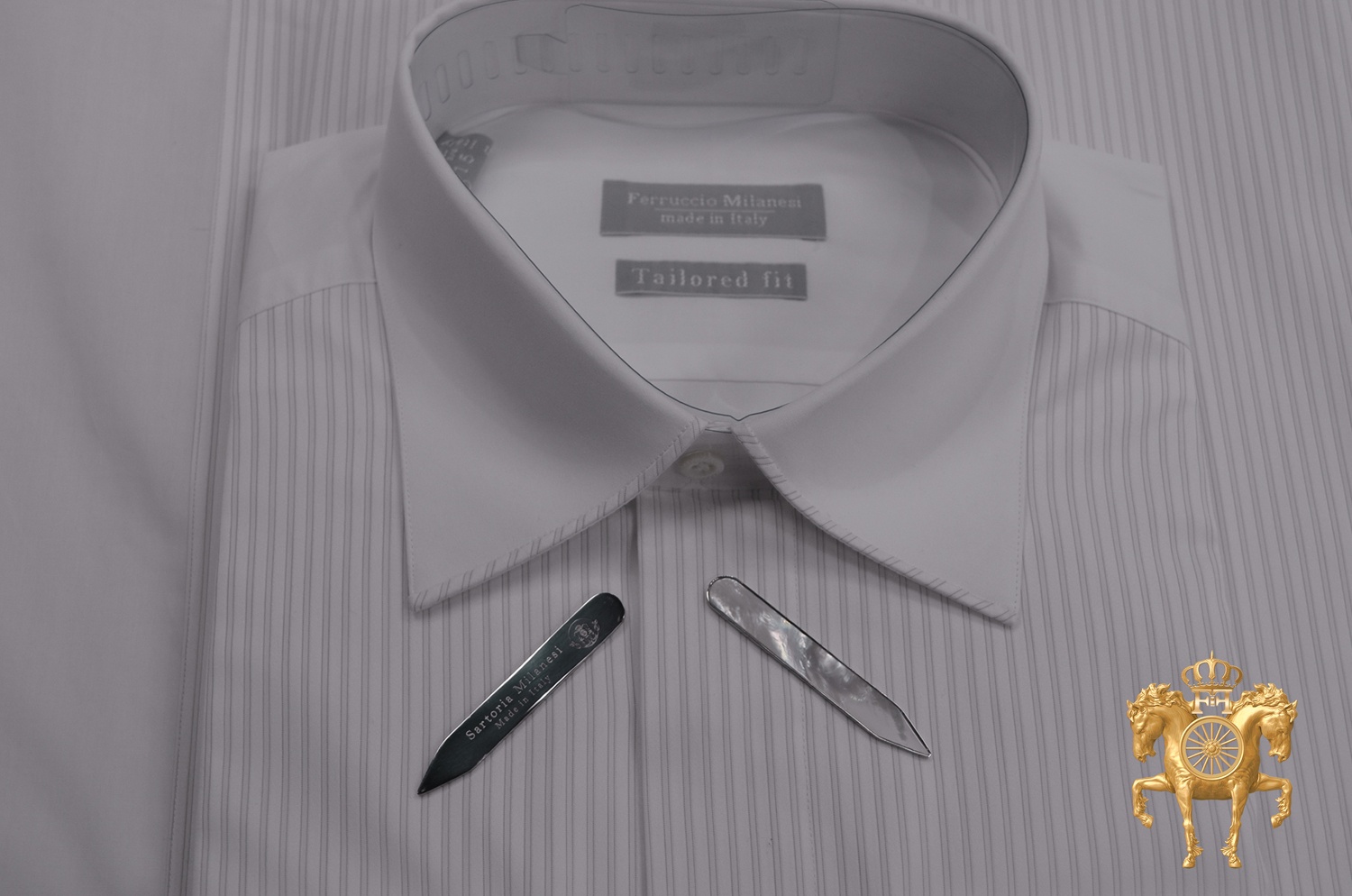

9) Collar stays.

9) Collar stays.

Most of the shirt makers in different brand positioning using plastic collar stay for their shirts, except a few sartorial luxury brands using MOP collar stays with metal support.

10) Sewing the buttons

The ideal way to sew the buttons on shirts is by sewing by hand and forming the shank. This will create extra space by creating the leg between the button and shirt fabric and eliminating tensions in buttoning aria. Otherwise, may you will see wrinkles around the buttons.

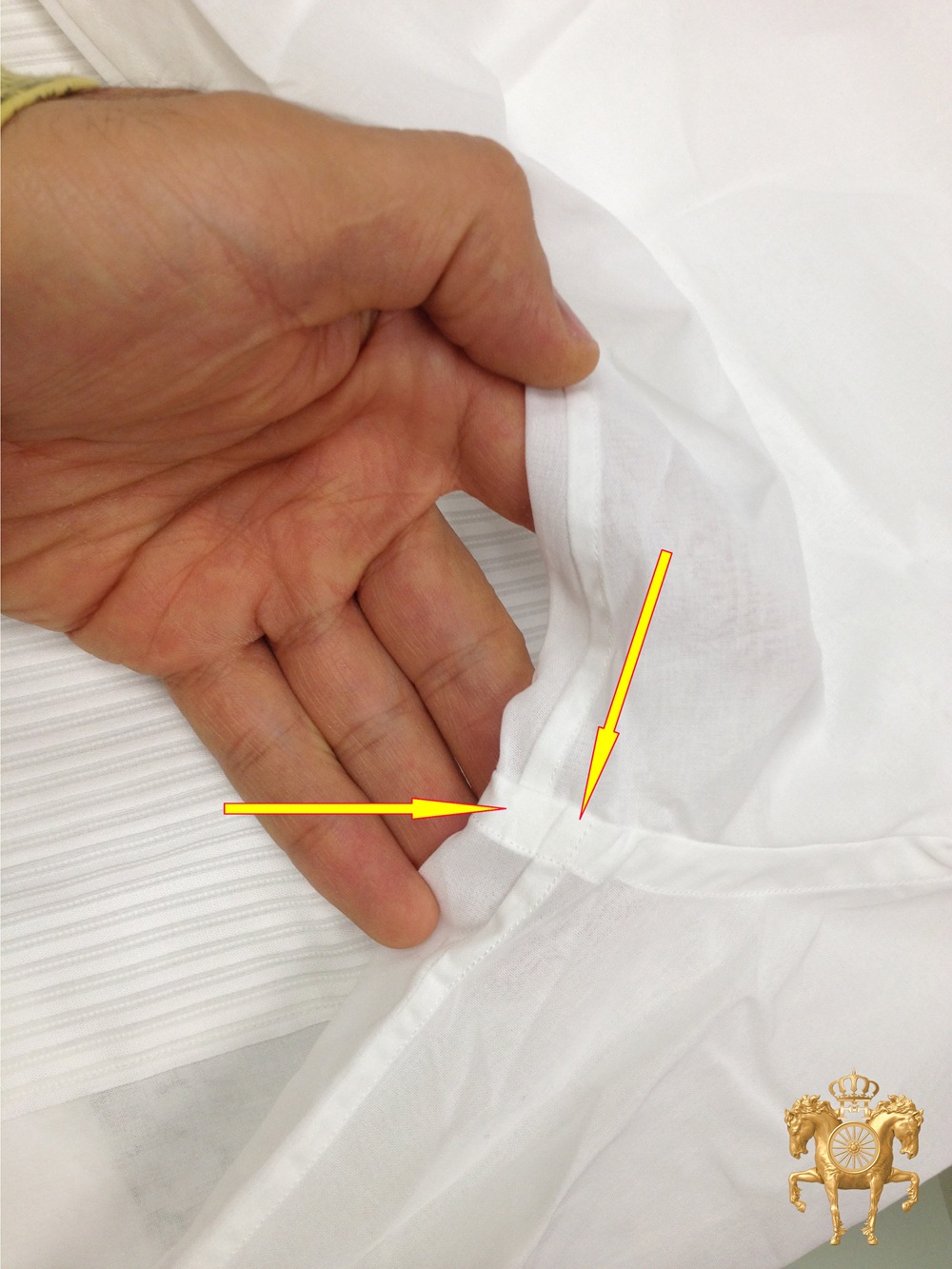

11) Attaching the sleeves to the shirt body

11) Attaching the sleeves to the shirt body

There are two types of construction to attach the sleeve to the body of the shirt.

a) Sewing the whole body part of the shirts and then add the sleeves.

This way shirt body takes its best stable shape, and connecting the sleeves after this stabilization, the shirt forms the body’s anatomic and natural shape. Keeping the sleeves to the end of the shirt manufacturing process is the best way to build a high-quality shirt. The crucial reason behind this is to create functionality and independent sleeves movements. In this type of construction, the body and sleeves seem not sawing in continue the line.

b) Sewing the body and sleeves at the same time in the same continue seems line.

In this type of construction, they are sewing the entire shirt together, the side seams of the body with sleeves seams simultaneously in the same continuous line. When the wearer moves his arms, the whole shirt will move together, and most of the time shirt will come out from trousers, and the sleeves rarely hang perfectly.

How to check? Look at the armpit shirts that will not match the side seam with the sleeve seam.

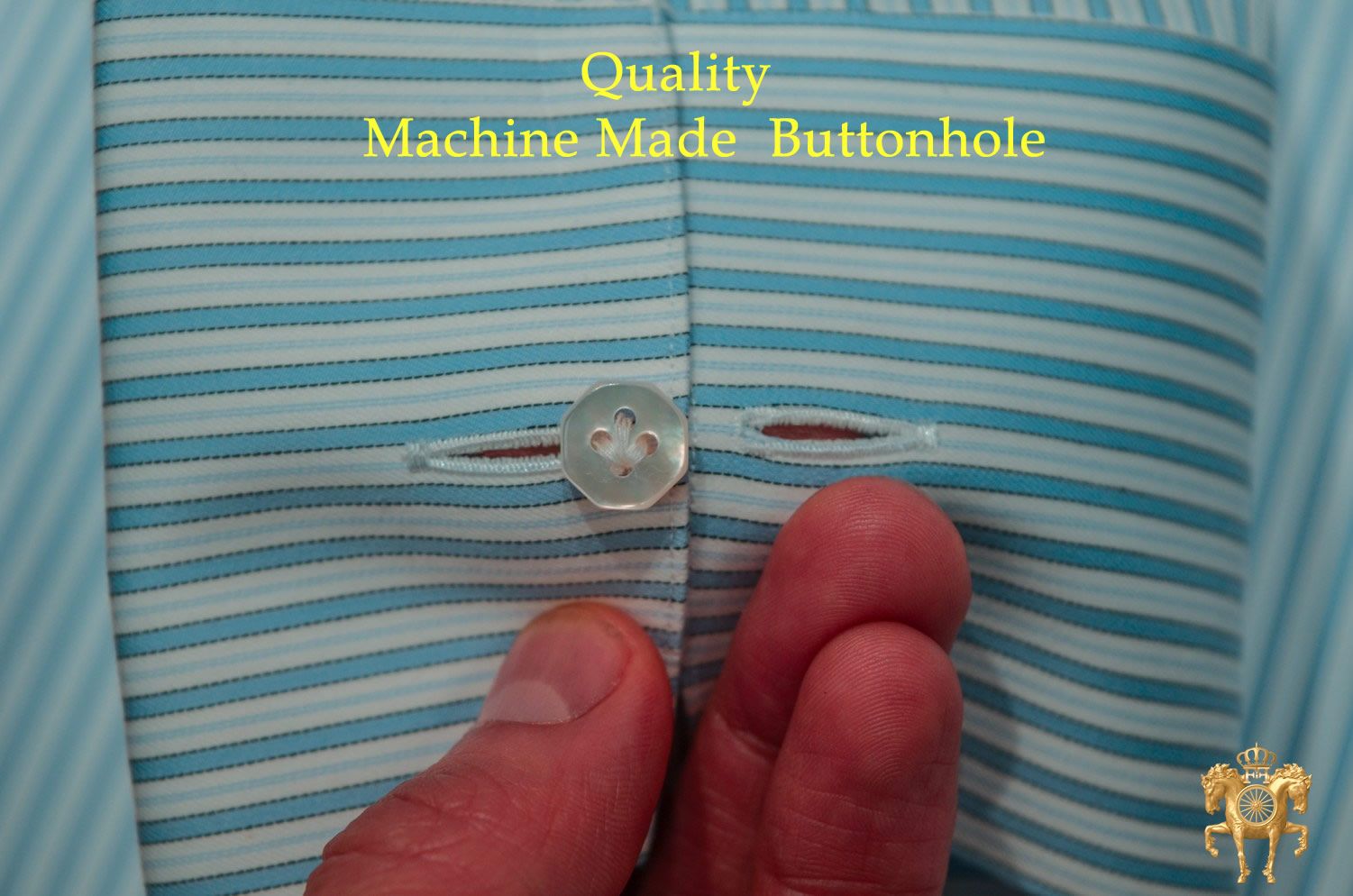

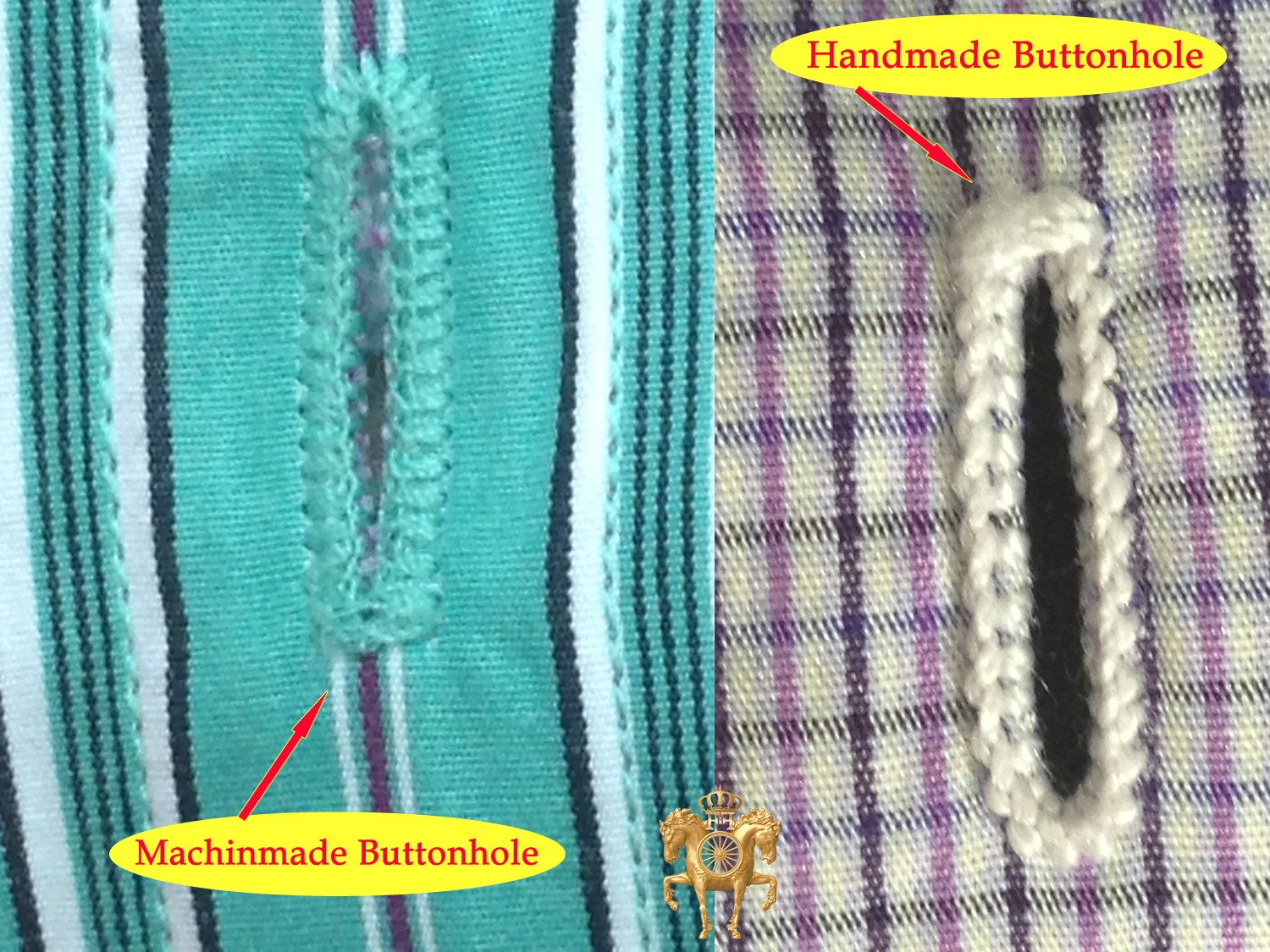

12) Buttonholes

12) Buttonholes

b) Sewing the body and sleeves at the same time in the same continue seems line.

In this type of construction, they are sewing the entire shirt together, the side seams of the body with sleeves seams simultaneously in the same continuous line. When the wearer moves his arms, the whole shirt will move together, and most of the time shirt will come out from trousers, and the sleeves rarely hang perfectly.

How to check? Look at the armpit shirts that will not match the side seam with the sleeve seam.

b) Using silk thread to make a buttonhole

Particular silk thread is the best option to create a Luxury look buttonhole. You can differentiate this by looking to buttonhole the color and shine of the thread.

c) Longevity and resistance

Machine-Made buttonholes because of robust weaving techniques will likely last longer.

d) Buttonhole positioning

The first buttonhole should be 45 degrees ( 9-12 o’clock). The body buttonhole’s position should be vertical, except the last horizontal, to create a little more room for expansion. The sleeve vent buttonhole is usually made in the same line as a sleeve and smaller. The hidden button is the most favourite on the sleeve vent. And cuff buttonholes are always made perpendicular to a sleeve line.

13) Side Gussets

13) Side Gussets

Side gussets are part of quality shirt elements. This future may not help comfort and functionality but is a part of the luxury shirt look and artisanal detail. Gussets are in different sizes and shapes with a sophisticated artisanal look.

14) Multi-functionality of cuffs

14) Multi-functionality of cuffs

The cuffs’ multi-functionality is the part of the high-end shirt but not necessary to have this future; it helps the wearer on any occasion and creates a different look.

15) Collar rest line

This future creates more comfort on the shirt’s neck backside when the neck is backward. This design and craft forming a comfortable seat for the neck.

16) Wrinkle-Resistant & Non-Iron Dress Shirts

Wrinkle-free and non-Iron tag in any shirt means poor-quality shirts. Because of the fabrics’ treatment, do not associate wrinkle-free and non-Iron dress Shirts with high-quality shirts. Beware of wrinkle-free labelled shirts.

17) Cotton – Silk mix fabrics

High-quality cotton fabrics and pure heavy silk fabrics are the best material option for a dress shirt. The last few year’s combinations of these two compositions have become more popular for luxury sartorial brand shirts.

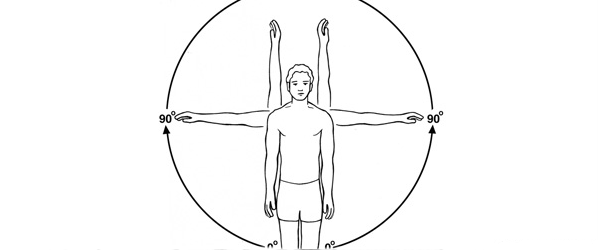

18) Small armhole and high Armscye

18) Small armhole and high Armscye

This future is the most exciting detail of luxury sartorial shirts. Cutting the small armhole in a unique shape creates much more room for the arms to have more free movement. This way shirt body and sleeves will move independently.

How to check?

To check this future, you should wear a shirt, tack it into the pant, and then move your arm in 90 degrees position with your body. Your shirt should stay in your trousers. And your arm movement will not affect the body part of the shirt.

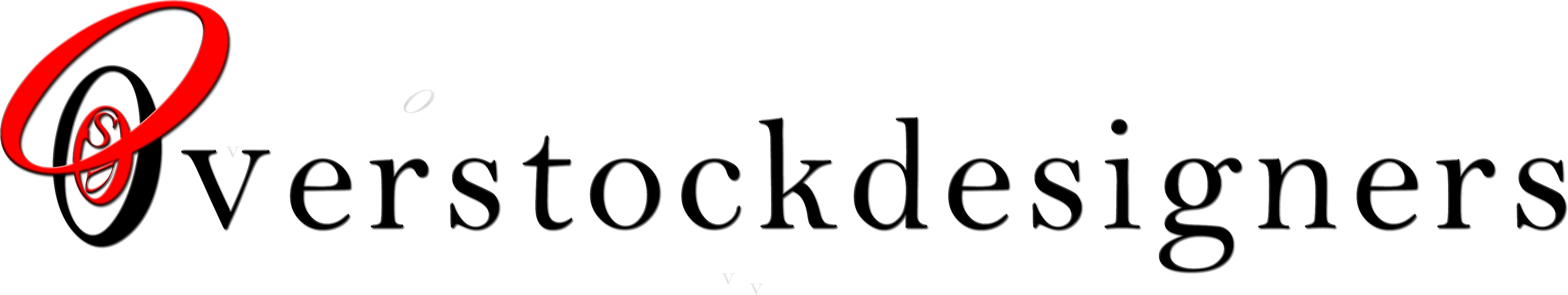

19) Yoke free dress shirts

A Yoke-free shirt is the ultimate innovative cut of the elegant look. The simplicity of this shirt cut always fascinated me. A Yoke-free shirt is the best choice shirt cut for those looking for something different, clean, and elegant.

20) Fit, Cut, and Size or Drop

We need to differentiate the right fit, cut, and size. Most of the time, people confusing these terms. It is an essential subject, and I am gone to cover this subject in depth soon.

Conclusion:

These days because of advanced advertising technology and dominant fashion industry influencers, we have been under attack 24/7 with wrong information. It is hard to make an objective decision to purchase freely.

We need to educate ourselves to build our wardrobe professionally with confidence and a clear plan behind every purchase for our wardrobe.

The above guidelines should help you choose the proper shirts for your wardrobe.

How to gain experience and educate yourself?

You can book 30 minutes of free advice in any of our locations, and one of our experts will meet you one-on-one and train you in everything in detail.

Or you can go to any men’s department store at your convenient time, train yourself, follow this guideline, check the shirts indifferent to the brand, and let your hand and eye become your expert tools. You do not need to buy, spend some time in luxury men’s stores, check the above details, and earn experiences for your next shopping.